ESBE IS AN EXCITING WORKPLACE

2024-04-09

It’s often said not to judge a book by its cover. Perhaps you wouldn’t expect to find one of Europe’s leading manufacturers of hydronic solutions in Reftele, a small town in Småland with barely 1,500 inhabitants. But it’s precisely here, amidst forests, fields, and waterways, that you’ll find ESBE’s headquarters. We’ve been here for over a century, with just under 200 dedicated employees, nearly 20 of whom work at ESBE Technology Center. This department develops and tests future products and creates sustainable, patented solutions. Among our colleagues, you'll find intriguing titles like testing engineer, mechatronics engineer, and innovation manager. Join us as we delve deeper!

Henrik Bäckman, head of development

ESBE’s technological core consists of high-class technology and sharp minds

Henrik Bäckman, head of development, quality, and environment in the ESBE group, leads the work at the department. When asked what makes ESBE Technology Center one of Northern Europe's leaders in its industry, he pauses before explaining:

“We have high capacity and excellent testing rigs. The team brings years of product experience, and proximity to production allows us to quickly adapt and create both cost-effective products and manufacturing methods.”

Henrik describes that the expertise covers both mechanics and electronics, and this knowledge can be combined with expertise in software programming. Overall, this means the test center develops complete products.

Missions signed by ESBE Technology Center

In addition to serving ESBE’s own departments, Henrik explains that there are primarily two customer groups that turn to ESBE Technology Center. One is the OEM customer. Here, the customer’s development team is connected with the developers at the Technology Center through a verified process. Often, the work involves assistance with mechanical and electronic control and connecting the ESBE product in the best way possible. An example of this is when Swegon turned to ESBE for help with developing a 6-way valve inside a comfort module for hotel rooms and public spaces. You can read more about the Swegon mission and a few others on ESBE’s OEM page.

The second customer group is the wholesalers, or distribution customers as ESBE calls them. This customer group sells ESBE products to installers and plumbers. Here, inquiries are based on the installers’ needs and the systems they work with.

Innovations from ESBE focus on energy and intelligence

Energy saving runs like a common thread through everything that happens at ESBE in general and at ESBE Technology Center in particular. We ask Henrik if he can provide some current examples of innovations that have improved the customer experience.

“As our business idea promises to provide property owners with the market’s most resource-saving products and solutions, this is our main focus. Everything revolves around this. We actively work to improve flows and energy in heating systems, and an example of this is our VRB140 and VRB240 valve series. These valves perform very well in bivalent heating and cooling systems. Bivalent systems mean that the valves can be used in a system with two heat sources, such as a heat pump and a conventional gas boiler.

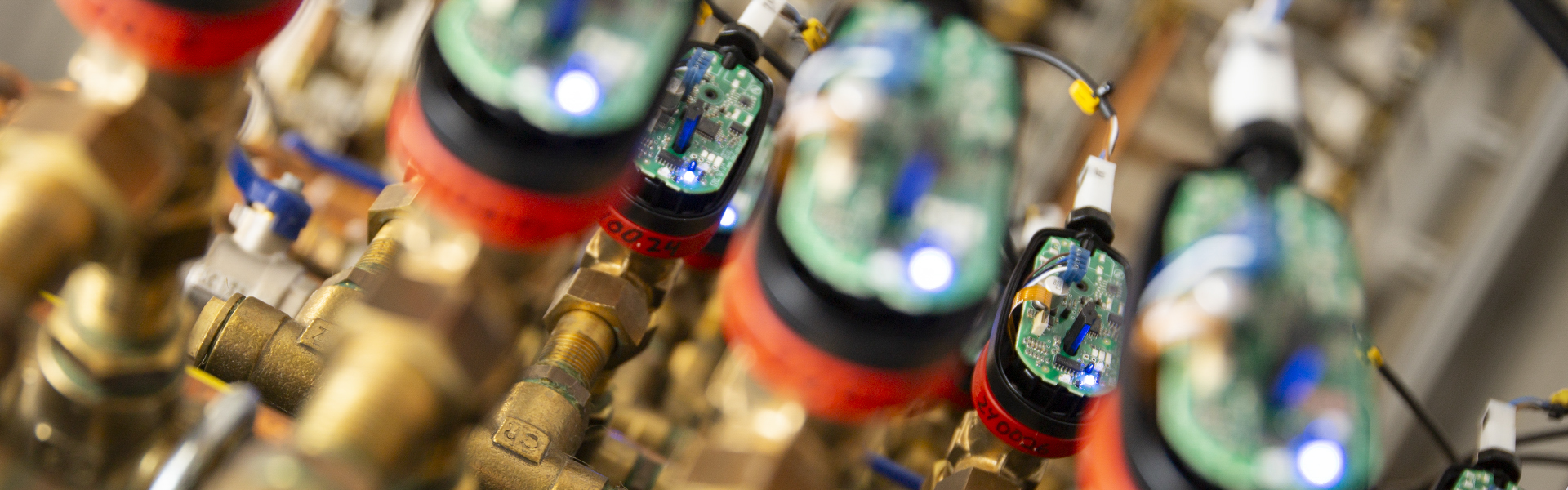

All of ESBE’s products help property owners direct energy to the right place and thereby create energy efficiency, but I also want to highlight that we also focus heavily on design and user-friendliness. We have developed intelligent valves designed with a feedback signal, which means the valve itself informs when it needs service or needs to be replaced. We have also developed products with a self-adjusting factor. This means that the product adjusts itself over time, which facilitates work for both plumbers and property owners.

Tamara, Caroline, Maria and Jonas employes at ESBE Technology Center

Where does the development team’s inspiration come from?

In the conversation with Henrik, we understand that high technical competence is required to develop ESBE’s products. Where does the inspiration come from, and how does the team keep track of trends and new technology? Henrik explains that there are several sources of inspiration. In addition to employees following industry organizations, they participate in seminars and trade fairs. They schedule study visits and have collaborations with colleges and universities.

“It’s important to have an ear to the market while also receiving a lot of guidance from EHPA (European Heat Pump Association). Intense discussions take place here at the highest EU level, with the goal of reducing the use of fossil fuels through, among other things, a heat pump action plan.”

ESBE has an inherent sustainability focus

If you read articles about ESBE, it’s clear that the sustainability philosophy is in the company’s DNA. Something that Henrik reinforces when he explains that every product is provided with a life cycle analysis (LCA). The life cycle analysis assesses the product’s environmental impacts throughout its lifecycle from raw material extraction and manufacturing to use and waste management.

“For us at ESBE, it’s obvious that all materials should be recyclable. To give a clear example, we can look at the valve series VRG. The materials are chosen for a sustainable life, the parts are replaceable, and the components are recyclable. When we use brass, the lead content is always below recommended limits. Since we want to create sustainable products, you can expect our products to have a lifespan of at least 15 years. Even the product packaging is made from recycled materials.”

When asked about how sustainability changes over time, Henrik explains that besides the ongoing internal sustainability work, they are also influenced by other factors.

“We listen to our customers through the channels we have with them, such as direct conversations but also through questions and requests that come into our own customer support. Our work is also influenced by EU regulations.”

Thanks to Henrik and the team at ESBE Technology Center!

We’re already looking forward to hearing more about tomorrow’s products.

Related links

ESBEs Technology Center »

ESBE, your OEM-partner »

Made in Sweden by ESBE »